3.3 Meters 3 Rolls Flatwork Ironer YP3300IIIZ/R

Features:

1.Single roller ironer with front and rear linen delivery.

2.Option for up to 6 rollers

3.Stainless steel rollers and high-temperature-resistant ironing belts ensure durability.

4.All mechanical parts are easily accessible for maintenance.

5.Safety features including baffles and limit switches.

6.Self-tensioned chain maintains correct belt tension

7.The intelligent controller enables flexible program settings based on linen types and humidity levels.

8.Automatically adjusts ironing speed and temperature

Product Features:

1.Single roll iron, front and rear linen delivery.

2.Self the chain to maintain the correct belt tension, reduce wear and prolong the life of the belt.

3.Safety functions, including the baffle and limit switch, can protect the operator from injury.

4.The intelligent controller supports flexible program setting based on flax type and humidity level. It can automatically adjust the speed and temperature of the ironing to achieve the perfect ironing quality and energy efficiency.

5.Roller heated ironer with an 800mm diameter. Option for up to 6 rollers for high-volume laundry.

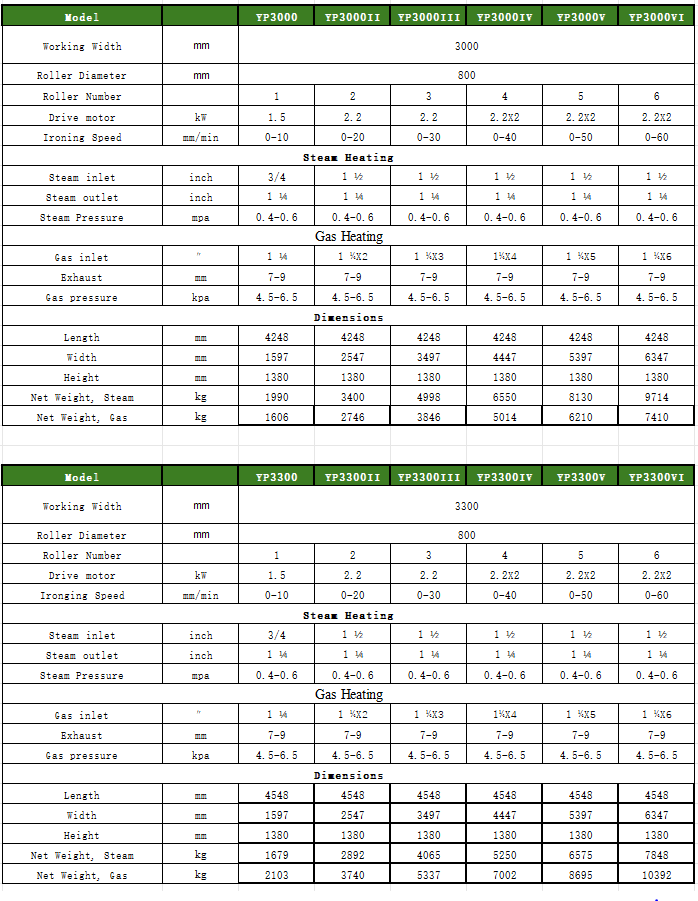

Product Parameter:

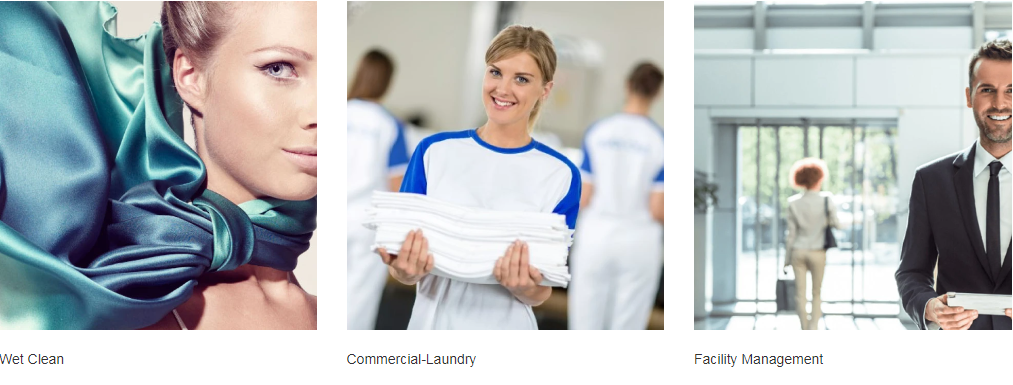

Product Application:

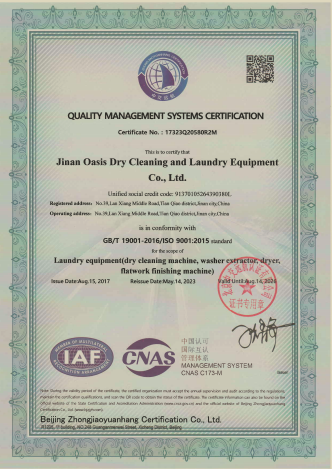

Company Strength:

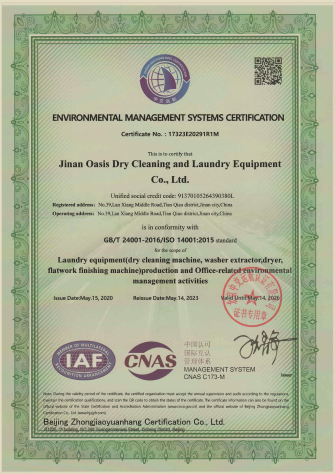

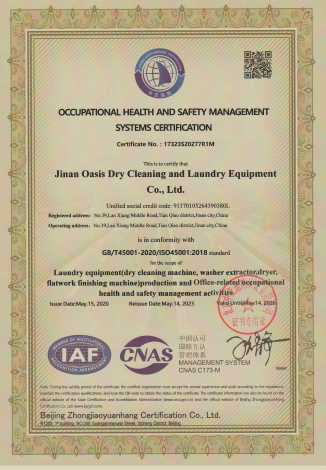

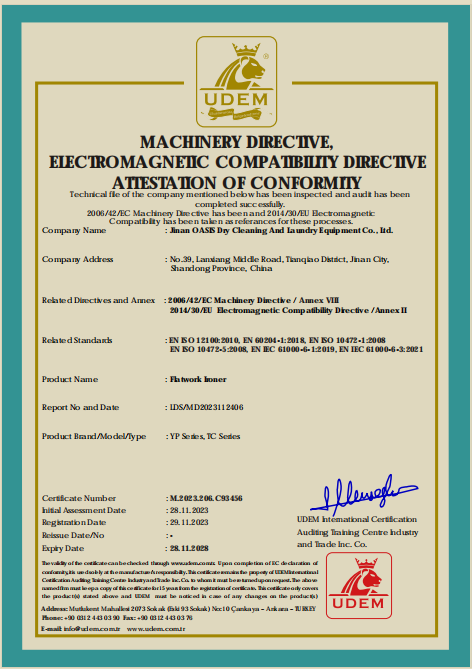

Product Certification:

Customer Communication: