The Operator’s Guide to Selecting Commercial Vended Laundry Equipment

Equipment selection is one of the primary factors that impact day–to–day operations of the coin-op laundry business as well as potential long‑term profitability and asset value for investors and operators. It covers the major engineering and operational aspects of professional-level vended laundry machines, which is a useful guide to making an informed capital investment. Contemporary laundromats and apartment laundry rooms need machines capable of striking a balance between being reliably functioning and running efficiently. Your washers and dryers’ technical specifications set direct controls on utility costs, maintenance frequency, customer satisfaction and therefore at the same time your bottom line.

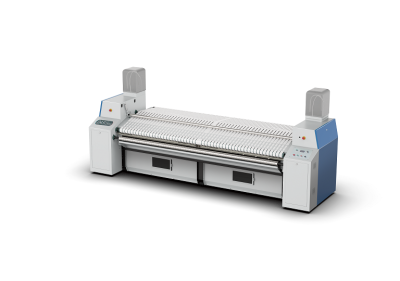

Technical Framework: Industrial Vended Machines & Their Major Components.

Professional vended equipment is characterized by the design and construction of its systems, built for an entire lifetime of heavy duty use well past a consumer-grade appliance.

1.Chassis & Drum Construction. It’s built on a massive steel frame and a high-grade stainless steel drum. This fights against corrosion, by detergents and continuous moisture, maintaining structural integrity for tens of thousands of cycles. All the parts of the drum, including the lifters and perforation pattern, are arranged for complete fabric turnover and water extraction efficiency.

2.Drive Systems & Performance. At the heart of the washer is the drive system. In practice, direct-drive motor systems run on commercial scale for higher spin speeds, sometimes over 300 G-force. This in turn results in better moisture extraction which in turn results in faster drying times and reduced energy consumption as part of the utility pricing equation.

3.Control Systems & Payment Integration. A good microcontroller controls such features of cycle choices, the water level, and the temperature. Payment systems have gone from coin-based to integrated, digital-supported to cashless/app-based payment. There are dual benefits of user friendliness and control and owners of remote revenue tracking and machine status diagnostics also.

Analytical Process: Turn the Technical Information Into Business Efficiency.

Equipment measurement involves translating technical specifications to operational measures. Here below is a table that illustrates how key engineering features influence the business results using data points seen with industrial grade vended machines like those manufactured by Oasis.

Technical Feature | Operational Impact | Business Outcome |

Stainless Steel Drum & Cabinet | Superior corrosion resistance, withstands harsh detergents and constant use. | Reduced downtime, extended equipment lifespan, lower long-term CAPEX. |

High G-Force Extraction (300+) | Removes more water from fabrics post-wash. | Shorter dry times (saving gas/electricity), increased daily turnover capacity. |

Programmable Control Systems | Allows customization of wash cycles (time, temp) for different fabrics. | Operational flexibility, can optimize cycles for utility efficiency or premium pricing. |

Remote Management Software | Enables monitoring of machine status, earnings, and alerts from anywhere. | Proactive maintenance, detailed revenue analytics, streamlined operations. |

Total Cost of Ownership (TCO): A Critical Evaluation Metric.

The purchase cost is just one component of the financial equation. A full TCO analysis for vended laundry equipment should cover:

l Energy & Water Efficiency: Machines with the highest efficiency ratings are able to reduce variable operating expenses as well; although some devices may be an expensive investment to begin with.

l Serviceability & Parts Availability: A layout that makes easy access to common components (belts, motors, sensors…) and an uninterrupted supply chain for spare parts reduce repair costs and machine idle time.

l Durability & Depreciation: Equipment built from commercial components has slower depreciation and a longer life, protecting your initial investment.

Towards a Future-proof Laundromat Equipment — Industry Update

Future-focused operators are exploring how next-gen features fit into existing investments:

l Cashless Systems: Making it a customer requirement, they reduce cash handling, promote dynamic pricing, and help market their items with loyalty programs.

l Internet of Things (IoT) Connectivity: Remote monitoring shifts maintenance from reactive to predictive, stopping minor problems from turning into major repairs.

Vended laundry equipment, for instance, would be one investment in the operational infrastructure to make sure your business is running smoothly. The decision will depend on engineering quality, data on efficiency being verifiable (including serviceability), and the focus on longevity and usefulness in a design philosophy. By paying particular attention to technical specs and the resulting reliability and lower operational costs, operators can better establish a more resilient and lucrative business. Performance and equipment specifications are modeled on industrial manufacturing standards for commercial vended laundry machines. Operators are encouraged to consult manufacturer’s detailed technical datasheets and lifecycle cost analyses with respect to specific procurement decisions.