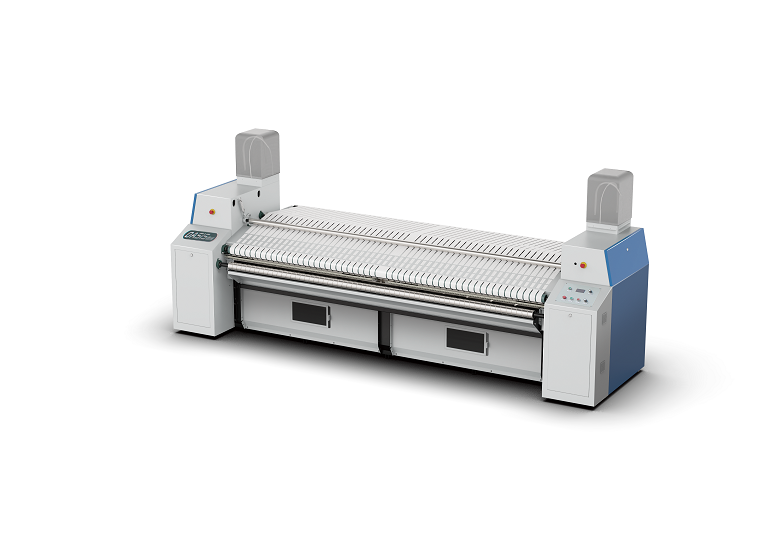

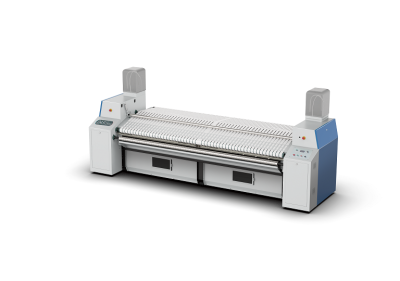

Flatwork Vaccum Feeder S-3300

Features

1.Vacuuming under the feeding table along with moving brush

2.Frequency inverter for automatic speed regulation with the ironing line

3.Buttons for activating/deactivating the vacuum and starting/stopping the conveyor

Product Details

Product Features :

1. Vacuuming under the feeding table along with moving brush

2. Suction box under feeding table holding linen tails

3. Frequency inverter for automatic speed regulation with the ironing line

4. Buttons for activating/deactivating the vacuum and starting/stopping the conveyor

5. Perfectly complementing with our ironers with working width of 3000mm and 3300mm

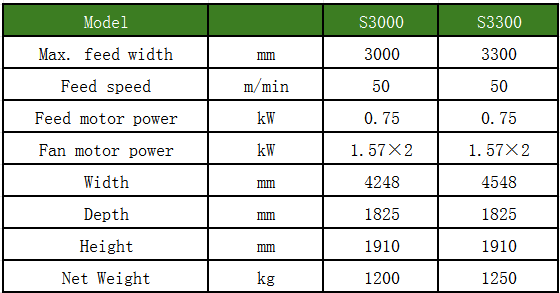

Product Parameter :

Product Application :

Company Strength :

Product Inventory:

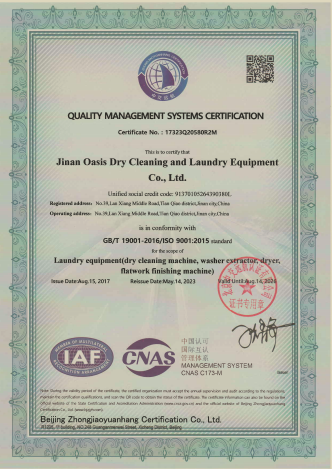

Product Certification :

Customer Communication:

Leave your messages