15KG Hardmount Washer Extractor SXT150GD/ZQ

Features:

1.Stainless steel drum, tub and door.

2.Clad steel panels resist rust and fingerprints

3.10kg model with direct drive motor

4.3D stereoscopic honeycomb-shaped inner drum with perforated lifters.

5.Permanently lubricated bearings

6.Mechanical and electronic double door locks, along with an emergency stop

7.Standard configuration includes 4 chemical compartments and 5 hoses for dosing pumps.

8.LED door light

Product Options:

1.Electric heating or steam heating.

2.Contact us for other requests .

Control:

1.Full-color touchscreen control offers 50 programs for OPL and 6 for vend.

2.Freely programmable and available in multiple lan-guages.

3.USB connection and networking capability.

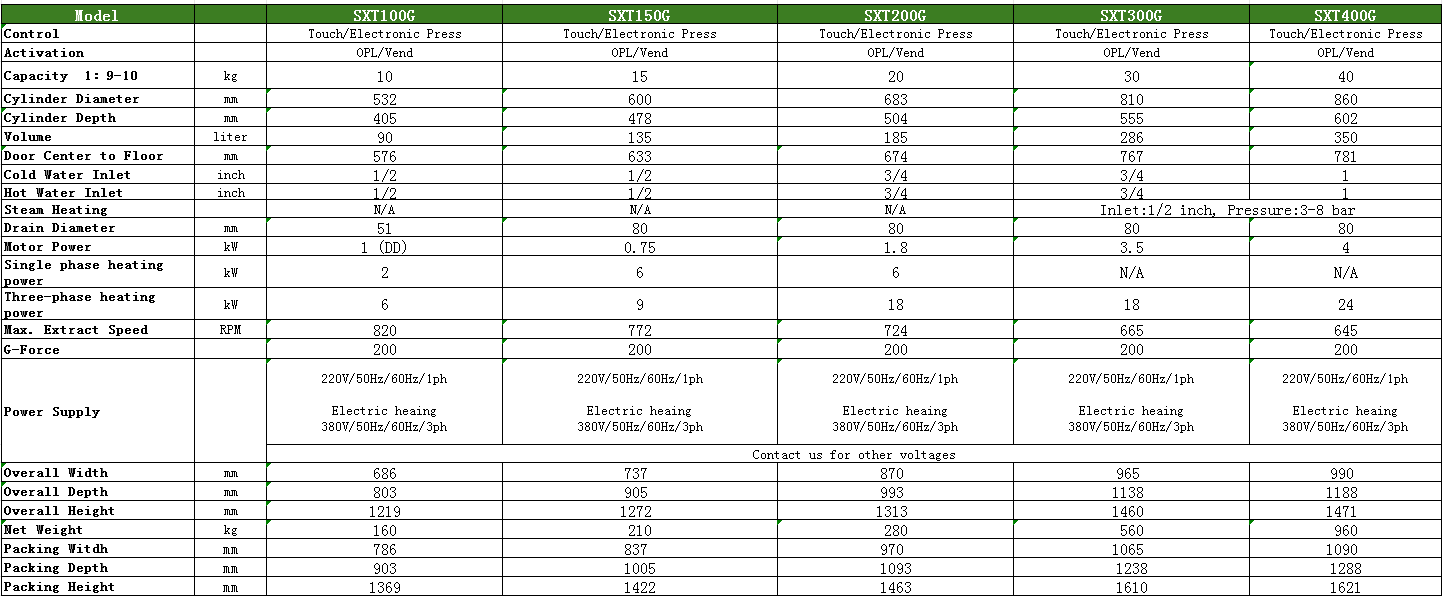

Product Parameter:

Product Application:

Company Strength:

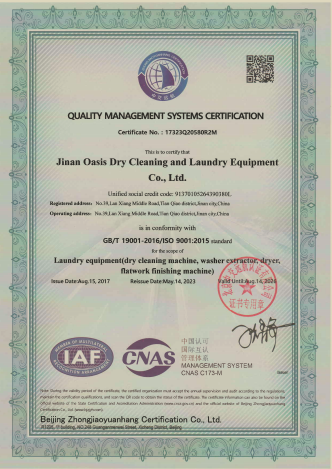

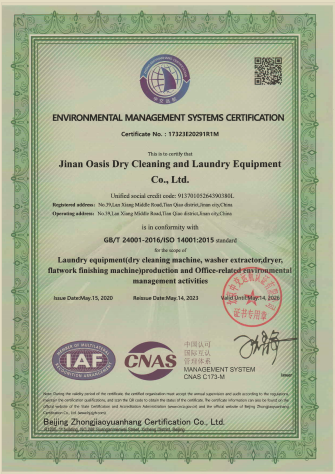

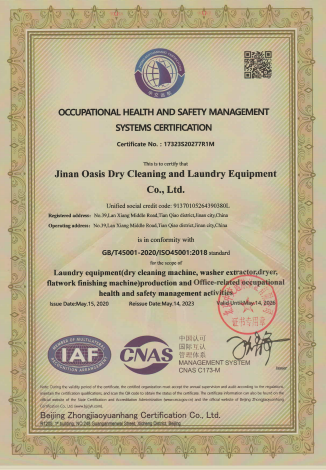

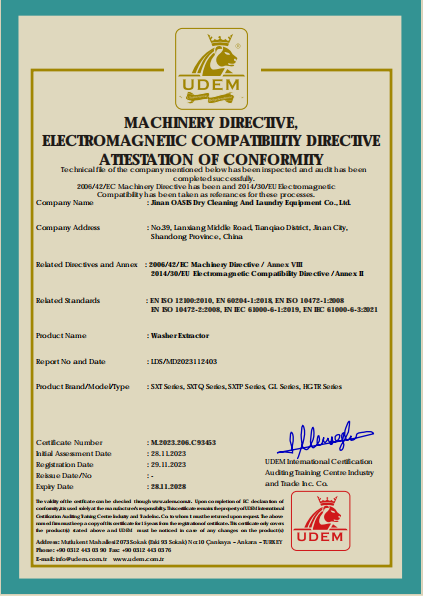

Product Certification:

Customer Communication: