100KG Heavy-Duty Tumble Dryer HG2000D/Z/RQ

Features:

1.Reversing Stainless steel cylinder

2.Painted carbon steel panels

3.Super large door with 180° opening. Optional slid door or flip door.

4.Heavy-duty door hinge ensures prolonged machine operation.

5.Inverter drive motor and fan motor

6.3D airflow and heat isolation

7.Optional moisture sensor

8.Optional forward tilting for 100kg slide door or flip door models

Product Features:

1.Painted carbon steel panels

2.Heavy-duty door hinge ensures prolonged machine operation.

3.Inverter drive motor and fan motor

4.Optional moisture sensor

5.Optional forward tilting for 100kg slide door or flip door models

Options:

1.Electric heating, Steam heating or Gas heating

2.Contact us for other requests

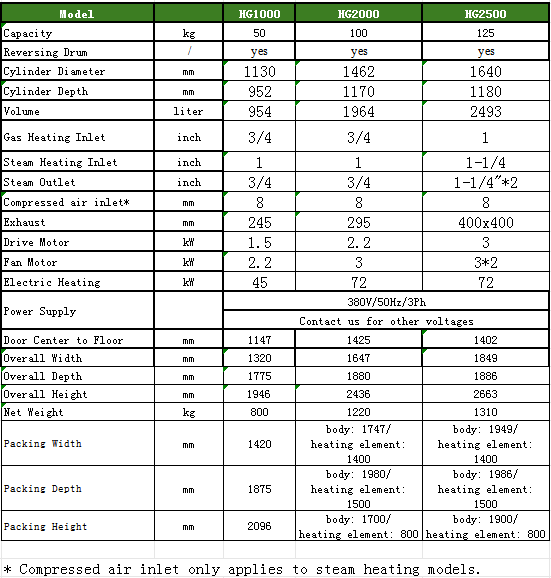

Product Parameter:

Company Strength:

Product Inventory:

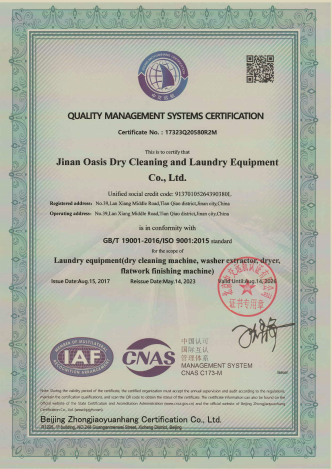

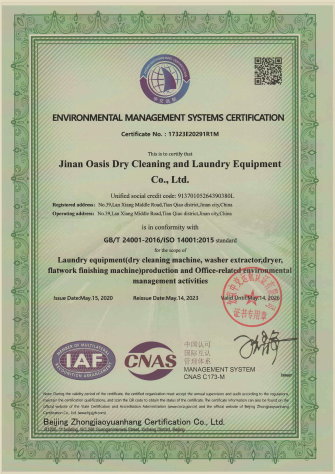

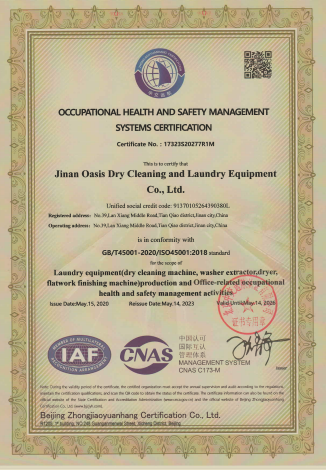

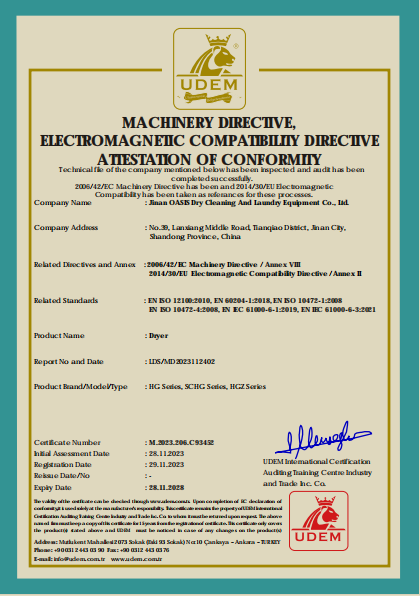

Product Certification:

Customer Communication: