110KG Barrier Washer Extractor GL110FD/ZQ

Features:

1.Clean unloading side is separated from soiled loading side

2.Softmount with air bags, springs, and shock absorbers.

3.Stainless steel drum, tub, and door,

4.Stainless steel panels

5.Permanently lubricated bearings

6.Intelligent electronic balancing system

7.Automatic positioning of the inner drum

8.Standard configuration includes 5 chemical compartments and 5 hoses for dosing pumps.

9.Mechanical and electronic double door locks

10.Heavy duty pnueumatic water valves, drain valves and steam valves

Product Features:

1.Standard configuration includes 5 removable chemical cup and 5 hoses for dosing pumps.

2.Mechanical and electronic double door locks, along with an emergency stop, ensure maximum safety.

3.Heavy-duty pneumatic valves control water inlet, drain, and steam.

4.Advanced inverter drive system ensures smooth start-up and energy savings, enabling longer machine life.

5.Optional 2 pockets for 110kg.

Options:

1.Automatic weighing

2.Programmable Logic Controller

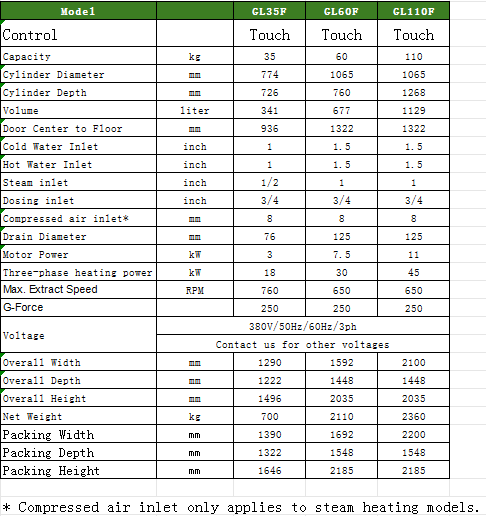

Product Parameter:

Company Strength:

Product Inventory:

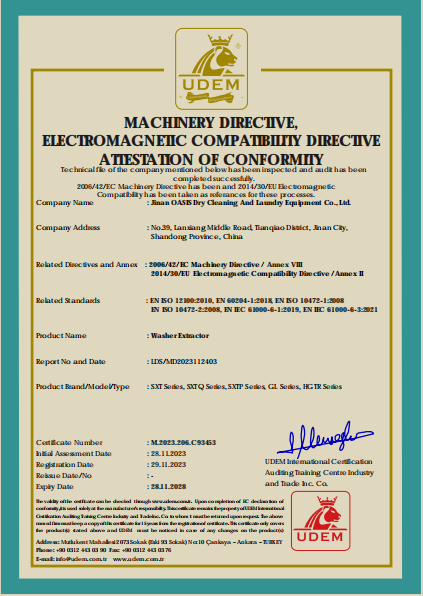

Product Certification:

Customer Communication: