10KG Commercial Multi-Solvent Dry Cleaning Machine HMS200

Features:

1.Compatible with various solvents including hydrocarbon, silicone-based solvents, K4 and modified alcohols.

2.Solvent recycle through segment vacuum distilling

3.Advanced anti-statistic technology

4.System prevent over distilling

5.Auto nitrogen injection system

6.Multi-level pressure and temperature safety guard

Control:

1.Skip steps applicable for auto cycle

2.Password protection available

Performance expert :

1.Patent-designed cylinder manufactured using the most advanced machinery achieves a maximum speed of 650 rpm .

2.Unique dual-invertor driving system ensures significant energy savings , smoother machine peration and minimal noise .

3.Two-stage vacuum distillation technology , isolating low-boiling-point contaminants from the solvent , greatly improves overall solvent cleanliness .

4.Hydro-Sens sensor realizes automatic waster drainage during the distillation .

5.Patent - designed solvent tank with bottom self - cleaning functionality .

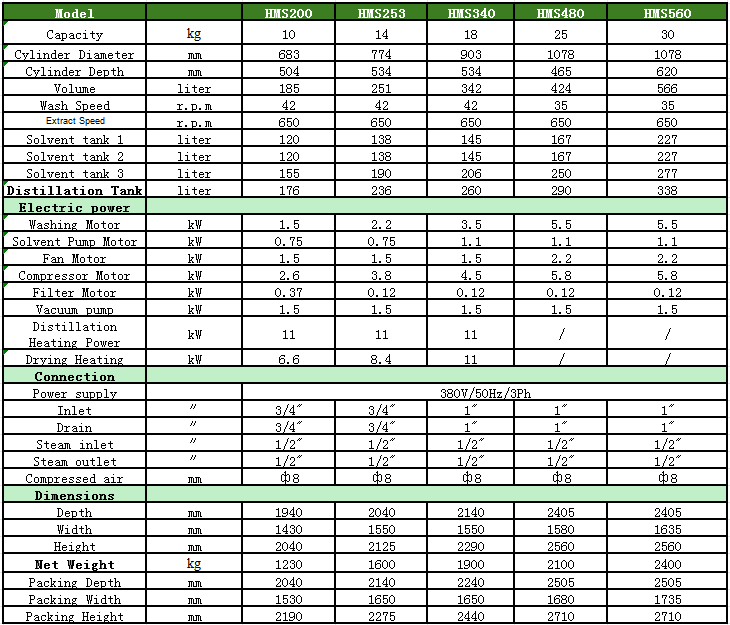

Product Parameter:

Product Application:

Company Strength:

Product Inventory:

Customer Communication: