30KG Industrial Perchlorethylene Dry Cleaning Machine P560FD/ZQ

Features:

1.All stainless steel structure

2.Solvent leak-proof base complies with CE standard

3.Refrigeration and heat pump recycling system

4.Centrifugal filter with high precision filer sheets that no need for filter powder or carbon powder

5.Cartridge filter for removing colors, odor and particles

6.Inverter drive motor and fan motor

7.Multi safety guards

8.Auto detergent injection

9.Second water separator

10.Standard auto-dry that adjusts drying time depending on load (except for the 8kg)

11.Optional solvent cooling

12.Optional distiller self-cleaning

13.External carbon based absorption system (not for PGX160F)

Product Features:

1.Centrifugal filter with high precision filer sheets that no need for filter powder or carbon powder

2.Cartridge filter for removing colors, odor and particles

3.Inverter drive motor and fan motor

4.Optional distiller self-cleaning

5.External carbon based absorption system (not for PGX160F)

Performance Expert:

The world's leading inverter drive system ensures significant energy saving and smooth machine operation with minimal noise.5. Large capacity double filtration system, a centrifugal filter and a carbon filter, guarantee excellent cleaning results, even for light-colored clothing.

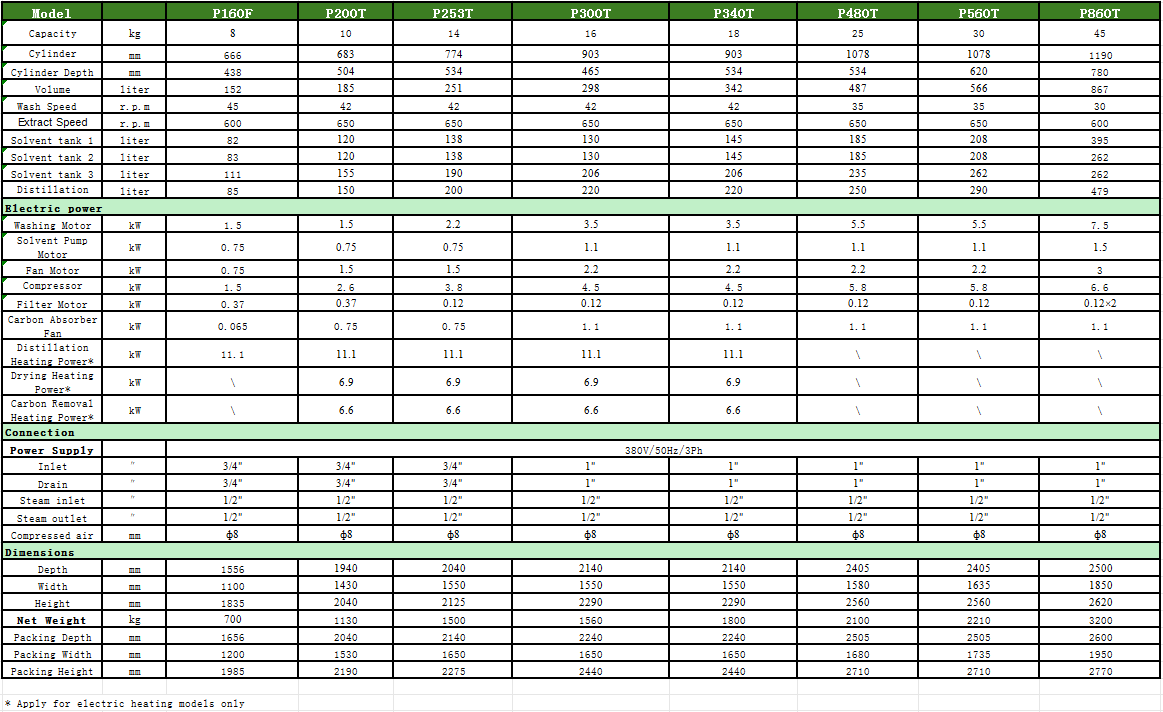

Product Parameter:

Product Application:

Company Strength:

Product Inventory:

Customer Communication: