20KG Touchscreen Softmount Washer Extractor SXTP200FD/ZQ

Features:

1.Stainless steel drum, tub and door.

2.Clad steel panels resist rust and fingerprints

3.3D stereoscopic honeycomb-shaped inner drum with perforated lifters.

4.Permanently lubricated bearings

5.Advanced suspension system, in conjunction with an intelligent electronic balancing system.

6.10kg washer utilizes direct drive motor, eliminating the need for belts.

7.All casting parts are well processed and painted.

8.Standard configuration includes 4 chemical compartments and 5 hoses for dosing pumps.

9.Mechanical and electronic double door locks

10.Advanced inverter drive system

11.Easy access to service parts from front and back panels

Product Features:

1.Advanced suspension system , in conjunction with an intelligent electronic balancing system , efficiently absorbs vibrations , reduces out-of-balance occurrences , and enables extraction G force up to 400 for shorter drying times .

2.10kg washer utilizes direct drive motor , eliminating the need for belts , minimizing maintenance requirements and allowing for more precise control of motor speed .

3.LED door light for visualization.

4.All casting parts are well processed and painted , ensuring machine longevity even in humid and harsh working environments .

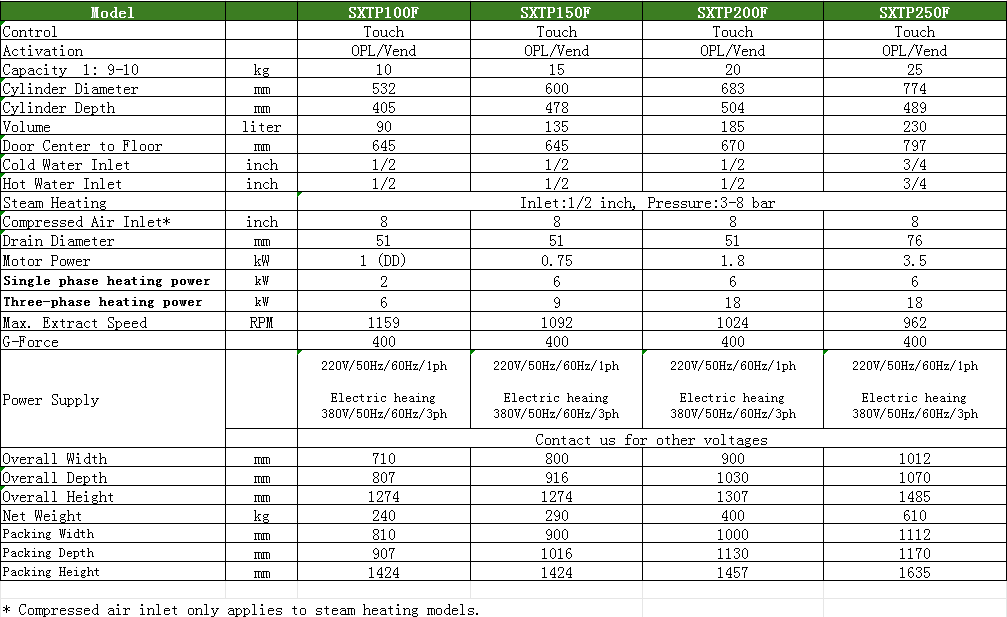

Product Parameter:

Product Application:

Company Strength:

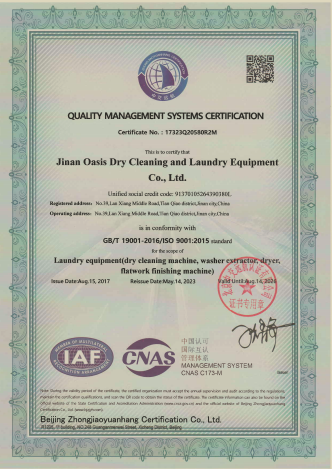

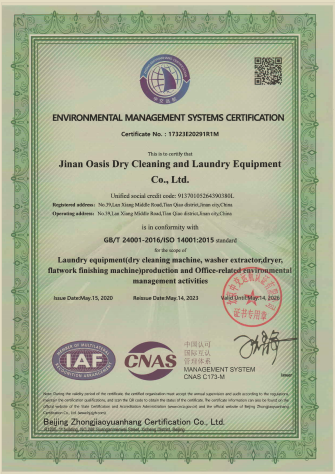

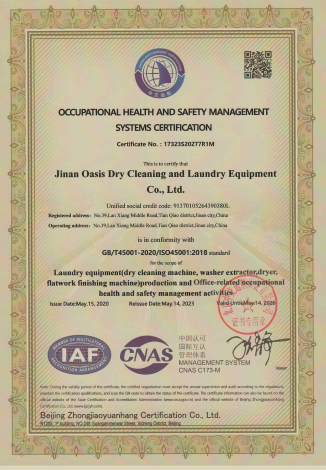

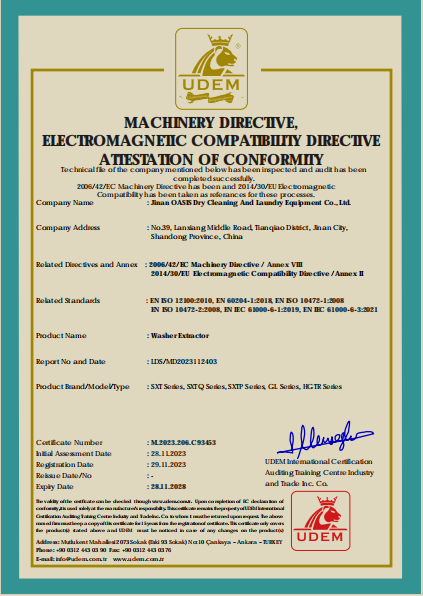

Product Certification:

Customer Communication: